As manufacturing enters the Fourth Industrial Revolution, traditional Lean methodologies must evolve to incorporate emerging technologies like AI, IoT, and advanced analytics. This article explores how Lean principles remain relevant while adapting to the digital age.

The Convergence of Lean and Digital

For decades, Lean manufacturing has been the gold standard for operational excellence, focusing on eliminating waste, improving flow, and creating value for customers. The rise of Industry 4.0 technologies presents both challenges and opportunities for these time-tested methodologies.

Contrary to some predictions, digital transformation doesn't make Lean obsolete. Instead, we're seeing a convergence where:

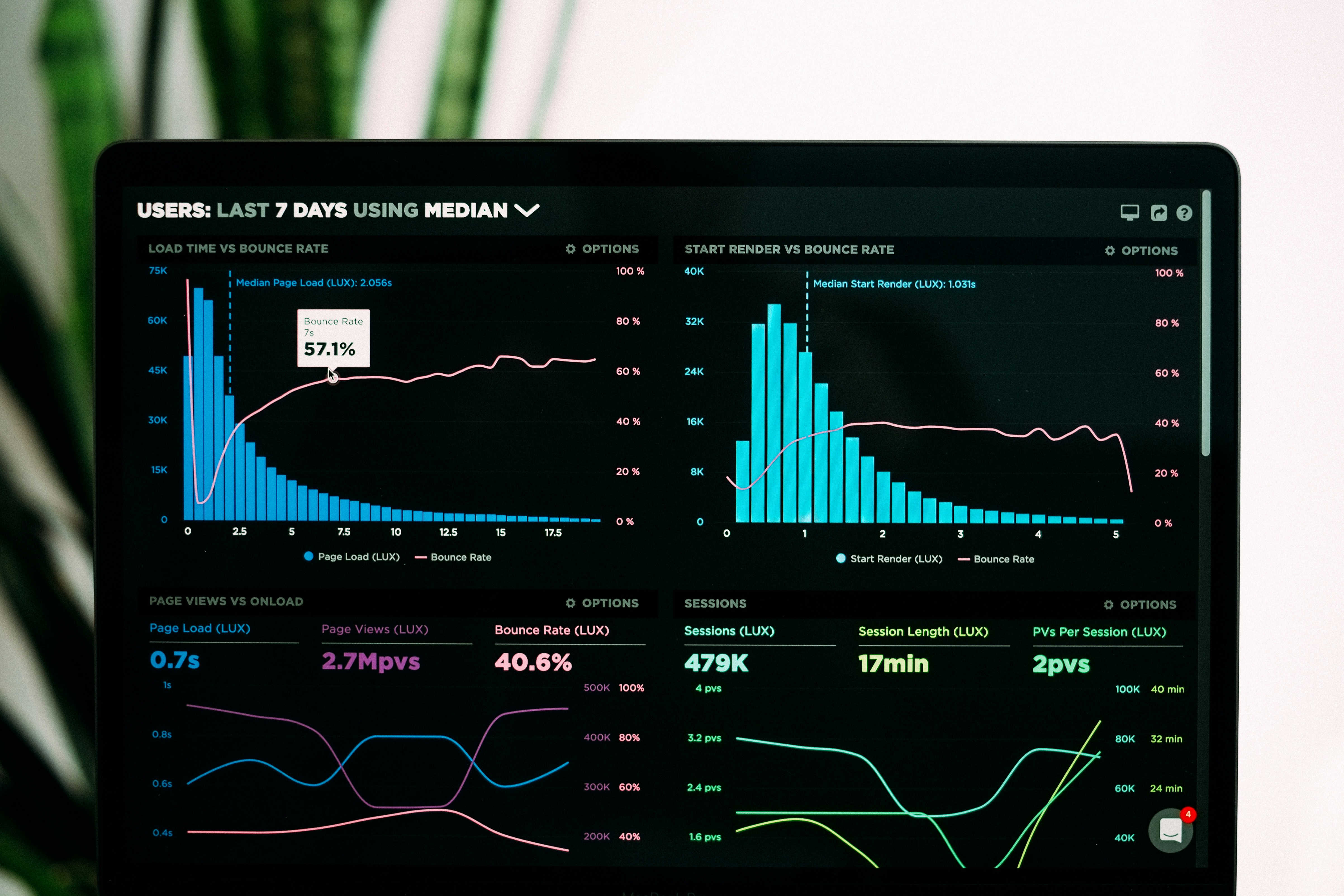

- IoT sensors provide real-time data for continuous improvement

- AI-powered analytics identify waste patterns humans might miss

- Digital twins enable virtual kaizen events

- Augmented reality enhances standard work documentation

Key Areas of Integration

1. Data-Driven Kaizen

Traditional kaizen relies heavily on manual observation and time studies. With Industry 4.0, we can now:

IoT sensors in a smart factory provide continuous process data

2. Predictive Quality

Six Sigma's DMAIC framework gains new power when combined with machine learning algorithms that can:

Implementing Lean 4.0

For organizations beginning this journey, we recommend a phased approach:

Assess Current Capabilities

Evaluate both your Lean maturity and digital readiness to identify gaps.

The most successful manufacturers of the future won't choose between Lean and digital - they'll find ways to make these approaches work together. By combining the human-centered philosophy of Lean with the powerful capabilities of Industry 4.0 technologies, organizations can achieve unprecedented levels of operational excellence.

Join the Discussion

Michael Rodriguez June 16, 2023

Great article, Sarah! We've seen particularly strong results combining digital work instructions with our standard work documentation. The visual nature of AR helps with both training and sustaining improvements.